LS-700: Designed for reliable performance in a lightweight package

Preventing Pressure Transducers From Drifting: What Is Pressure Sensor Drift?

Traditionally pressure transducers drift over time and during installation. This has been a continual problem that requires the end user to offset their readings either at the pressure transducer/sensor or the data acquisition system.

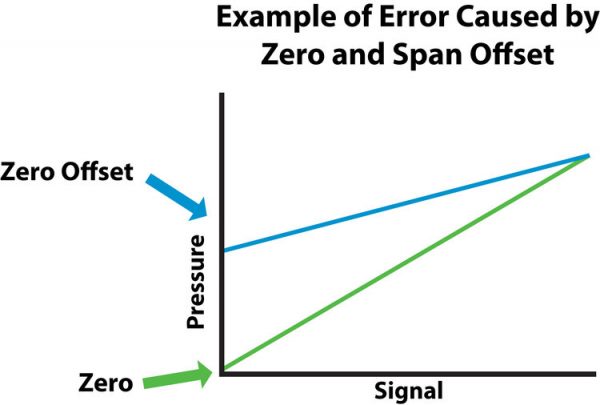

The traditional fix has been zero and span potentiometers. However, the offset of the zero has eliminated the original factory calibration by offsetting the curve. This results in inaccurate readings. (See Figure 1)

Throughout this article we are going to look into what exactly pressure sensor & transducer drift is, what causes a pressure sensor to drift and what you can do about the problem.

Firstly, What Is Pressure Sensor Drift?

Pressure sensor drift or pressure transducer drift is the gradual degradation of these components which causes readings to offset from their original calibration. Drifting causes the accuracy of your pressure sensor or transducer to diminish over time, providing unreliable pressure sensor readings and measurements.

Depending on the senor or transducers’ application (water pressure sensors, water level sensors, pressure switches etc), each component will be made from different materials, and when exposed to certain conditions, these components will change over time depending on the application and materials of the component.

Components will expand and contract when subjected to extreme pressures and temperatures and will also be affected by other environmental factors, such as pressure change frequency and material responses.

Pressure sensor drift affects your pressure sensor value and the reliability and accuracy of your readings.

Pressure sensor accuracy is particularly important when looking for reliable measurements and data.

All types of pressure transducers and sensors are liable to drift/shift over time, no matter the manufacturer, cost or precision of the component.

Why Do Pressure Sensors & Transducers Drift?

Transducers have drifted due to several reasons but some of the most common include physical damage to the diaphragm and curing of the bonding adhesive between the diaphragm and the strain gauge over periods of time.

As with most components, pressure sensors and transducers are likely to degrade naturally over time. However, there are plenty of other factors which will affect pressure transducer accuracy.

For example, the improper installation of components can greatly affect a pressure senor or transducer’s accuracy and lifespan. Application variables such as temperature, turbulence, barometric pressure, specific gravity etc can all kill the accuracy of your components, although many of these variables can and are compensated for – for example temperature compensation.

It is worth pointing out that drift is to be expected and is common within pressure sensors. Unlike other types of sensors, sensor drift is the result of diaphragm and bonding construction, something specific to piezoresistive pressure sensors, transducers, transmitters, governors and gauges.

What Causes Pressure Sensor Drift?

There are various factors which cause pressure sensor drift. As already mentioned, it is a natural phenomenon specific to pressure sensors and similar components.

Some of the most common causes of pressure sensor drift are:

Improper Installation

The improper installation of pressure sensors and transducers is one of the most common contributors to drift, affecting your pressure sensor accuracy.

Curing of Adhesive

The curing of the bonding adhesive between the diaphragm and strain gauge over periods of time will contribute to pressure sensor and transducer drift.

Physical Damage

The physical damage of a component, for example damage to the diaphragm, can seriously contribute to pressure sensor zero drift.

Application Variables

Fluctuations in application variables such as temperature, pressure, turbulence etc can all cause pressure sensor offset drift.

How To Detect Pressure Sensor Drift?

Pressure sensor drift detection can be tricky, especially if the drifting differential is only marginal to begin with. A high drift will be more easily identifiable but how can you detect a pressure sensor drift which isn’t so obvious?

Manual pressure measurement would be necessary in this circumstance, wherein routine manual pressure measurements are compared to the readings taken by your datalogger/monitor.

Contact Texas Sensors & Controls Today To Find Out More About Detecting Pressure Sensor Drift…

How To Stop Pressure Sensor Drift?

Pressure sensor drift is mostly inevitable, it is a natural process. However, in some circumstances pressure sensor drift correction is possible. Correcting for drift is sometimes possible through factory re-calibration or by Pressure Transducer Zero Drift.

It is always worth reviewing your pressure sensor’s specifications or data sheet to see what the manufacturer recommends you do about pressure sensor drift for your individual sensor.

Ofcourse, if you want to prevent premature pressure sensor drift, then it is essential for you to have the correct pressure sensor for your intended application and for it to be installed correctly from the outset. You also want to ensure no physical damage or curing of adhesive. You can eliminate the adhesive completely by using sputtered film deposition (See Figure 2). The sputtering technique causes the signal per deflection to increase dramatically, meaning the diaphragm flexes less for an equivalent pressure. Therefore, we are able to use a thicker diaphragm, which will cause no physical damage.

Want To Find Out More About Pressure Sensor Drift?

If you would like to find out some more information about pressure sensor drift, accuracy and correction, or to access reliable support and help for your pressure drift problems, then please get in touch with Texas Sensors & Controls today. Texas Sensors & Controls’ core principle of business is to technically engage with customers to engineer a superior solution for all. To find out more about pressure transducer/sensor drift then please get in touch via our contact form, by emailing us at sales@txsensors.com or by calling us on 281.655.9902 and one of our friendly team of engineers and support staff will be happy to assist you.